ns. The repairs that had been made to the bottom of the hull were hideous and very poorly done. Calvin Clissold was the Chief Designer at Gulfstream Boats in Salt Lake City, Utah. I had just been laid off from Gulstream after tooling up three new boats for them. Cal and I had worked together for over three years on those projects. I had also worked for Gulfstream a few years before that. He had approached me to inquire if I'd be interested in properly repairing and making some huge modifications to this boat. Totally reinventing it. I didn't commit to the project right away. I was not concerned about being able to do it. I immediately realized the tremendous cost and time involvement it would require. Bill Laird assured both Cal and me that it would not be a problem. Cal was very careful about making Bill realize it would be more cost effective to buy a new boat similar to this one. Bill would not hear of it. Cal and I concluded that Bill was sentimentally attached to the poor thing.

ns. The repairs that had been made to the bottom of the hull were hideous and very poorly done. Calvin Clissold was the Chief Designer at Gulfstream Boats in Salt Lake City, Utah. I had just been laid off from Gulstream after tooling up three new boats for them. Cal and I had worked together for over three years on those projects. I had also worked for Gulfstream a few years before that. He had approached me to inquire if I'd be interested in properly repairing and making some huge modifications to this boat. Totally reinventing it. I didn't commit to the project right away. I was not concerned about being able to do it. I immediately realized the tremendous cost and time involvement it would require. Bill Laird assured both Cal and me that it would not be a problem. Cal was very careful about making Bill realize it would be more cost effective to buy a new boat similar to this one. Bill would not hear of it. Cal and I concluded that Bill was sentimentally attached to the poor thing. We then adjourned to a coffee shop to further discuss what would be done and come to an agreement. At that time Cal introduced this line drawing of basically what he had in mind. It almost blew me away. I began to have second thoughts. Cal assured Bill Laird that I could do it single-handed and that if I should need any help, Cal could make his son Jim available. Jim and I had worked together at Gulfstream so I was fine with that.

The boat was crammed into the back of a large cabinet shop in an industrial complex where I spent the first year removing and properly repairing the damaged areas on the bottom of the hull. After that I added a quarter of an inch of new fiberglass over the entire bottom from the inside(working inside between the main deck and inside of the bottom). Then the entire bottom got two layers of 1/2" balsa core and fiberglass inside. After that had cured, another 1/8'" of fiberglass completed the hull redo. It was literally bullet-proof on the bottom.

The first restyling modification was the raised shear-line on the bow of the boat. It became apparent early on that Bill Laird fancied himself a boat designer. He insisted on changing what Cal had called out for this modification right off. Bill demanded that I build it the way He (Bill) wanted it. In the three months it took to build, Bill and Cal got into some very heated discussions about the appearance of this first modification. Cal insisted it ruined the sweeping line of the bow and spoiled the overall flow visually.

The first restyling modification was the raised shear-line on the bow of the boat. It became apparent early on that Bill Laird fancied himself a boat designer. He insisted on changing what Cal had called out for this modification right off. Bill demanded that I build it the way He (Bill) wanted it. In the three months it took to build, Bill and Cal got into some very heated discussions about the appearance of this first modification. Cal insisted it ruined the sweeping line of the bow and spoiled the overall flow visually.

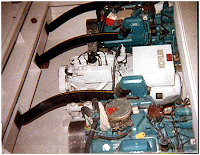

The engine bay with the twin Chevy's and the Kohler Power Generator nestled in between.

This picture shows off the gracful sweep of the bow that Cal fought so har for. It added over 9" to the overall length of the craft. It was still classed as a 50 footer.

This picture shows her nearly finished as far as my part of the project. There is a seat that curves with the walk-way around the bridgeside to side just below the shear-line and just ahead of the three windows. Access to the bow is through the opening in the walk-way in front of the bridge.

We even mocked-up the handrails before having them made.

.JPG)